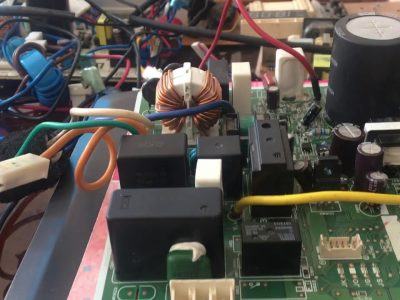

In the process of repairing the Chiller, there are a number of main reasons that make the machine easily damaged such as:

1. Non-genuine replacement oil and refrigerant, causing muscle contraction and compressor fire

2. Failure to clean and maintain the chiller periodically, leading to the cooling of the poor gas chiller running hot for a long time can also cause damage to the compressor head.

3. When replacing gas, oil allows moist gas to enter the system, causing moisture blockage and water compressor failure.

4. When repairing, fixing system leaks, letting welding slag or metal chips when cut into the system, these dust can bombard and damage the insulating paint causing a fire to the compressor, block chiller Hitachi.

5. Caused by the power supply being reversed, phase lost, overcurrent, but the protection device does not disconnect, it can also damage the refrigerant compressor of the chiller.

6. Due to the principle that the compressor runs for a long time, the insulation will gradually decrease and lead to a compressor fire.

During operation, when a problem occurs with the Chiller, despite being knowledgeable about the operating principle of the machine, the repair is not easy. To repair you need professional technicians so that production and business are not affected. GL Commerce Co., Ltd provides Chiller repair and maintenance service, with a dedicated and professional staff that will help you quickly fix Chiller machine repair.

Contact us: GL Commerce Co., Ltd

Address: Thien Ke Hamlet, Thien Ke Commune, Binh Xuyen District, Vinh Phuc Province

Hotline: 02113.555.688

Gmail: contact@glcomvn.com.vn

Web: Glcommerce.com.vn