In an automatic control system, a PLC ( Programmable Logic Controller) is a programmable (programmable) control device that allows flexible execution of logic control algorithms through a programming language. the heart of the control system. With a pre-installed application program, the PLC Controller continuously checks the status of the system including: checking the input signals, relying on the logic program to process the signals and carry the signals. control signal to the output device.

User programmable to perform a series of events. These events are triggered by stimuli (inputs) acting on the PLC or through delay operations such as time or other events. PLC controller used to replace relay circuits (relays) in practice. The PLC controller works by scanning the input and output states. When there is a change in the input, the output will change accordingly. The programming language of a PLC can be Ladder or State Logic. Currently, there are many manufacturers of PLCs such as Omron, Allen-Bradley, Siemens, Honeywell…

What is the working principle of PLC controller?

When the device is activated (ON or OFF state due to external physical control device). A programmable controller will continuously loop a user-defined program (loop) and wait for signals to appear at the input and output the signals at the output.

To overcome the disadvantages of wired controllers (relay controllers), a PLC controller has been created to satisfy the following requirements:

+ Easy programming, easy to learn programming language. + Compact, easy to maintain and repair. Large memory capacity to accommodate complex programs. + Completely reliable in industrial environments. + Can communicate with other smart devices such as computers, network connections, expansion modules. + Competitive individual prices.

Structure of the PLC controller.

All PLC controllers have the main component: An internal RAM program memory (expandable with some external memory EPROM). A microprocessor has a communication port for pairing with a PLC. I/O modules.

In addition, a complete PLC controller comes with a manual or computer programming unit. Most simple programming units have enough RAM to hold the program in complete or complementary form. If the programming unit is a portable unit, the RAM is usually CMOS type with battery backup, only when the program has been tested and is ready for use will it be transferred to the PLC memory. Large PLCs are often programmed on a computer to support writing, reading and checking programs. The programming units connect to the PLC via RS232, RS422, RS485, …

Application of PLC controller.

– Transport lifting system.

– Packing line.

– The robot assembling the product armor.

– Pump control.

– Chemical processing line.

– Paper production technology.

– Glass production line.

– Cement Production.

– Food processing technology.

– Semiconductor component manufacturing line.

– TV assembly line.

– Control the traffic light system.

– Automated parking management.

– Alarm system.

– Industrial sewing line.

– Elevator control.

– Automobile production line.

– Manufacture of microchips.

– Check the production process.

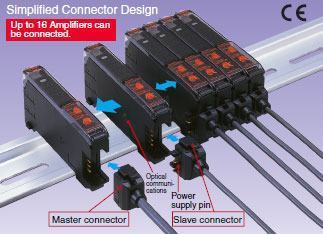

Common PLC controllers of Omron Company.

– Small PLC controller CP1E, lowest cost, USB port programming, maximum support 180 I/O.

– Small, versatile PLC controller CP1L, available with USB port supporting up to 180 I/O, with built-in Ethernet model CP1L-E.

– Small PLC controller, the most powerful feature CP1H, USB port programming, maximum support 320 I/O.

– High-performance modular multiplexed PLC controller CJ2M, available USB port supports up to 2,560 I/O.

– The most powerful modular coupled type PLC controller CS1/ CS1D, maximum support 5,120 I/O.