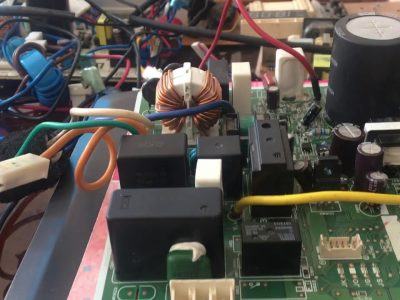

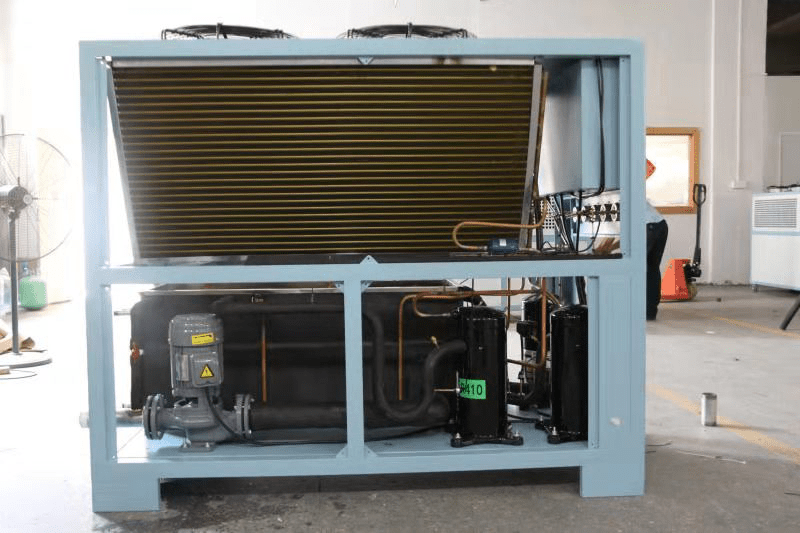

The compressor is the most important device in the chiller system. The compressor has the common effect and task is to pump and circulate the refrigerant in the system, so that the refrigerant will pass through the cooling system and depending on the user needs, the user will use the compressor. cooling or evaporator for the intended use. Thereby we can see that without the compressor, the chiller system cannot work.

Currently there are compressor types such as: helical, bittong, screw, roller rotor, centrifugal and most of these compressors are constructed and designed by mechanical specifications. During use or operation of the compressor, because the compressor head is a mechanical part, it will need oil to lubricate and cool the machine part.

Effect of oil change on chiller compressor

– Reduce friction: compressor oil will prevent metal surfaces from coming into direct contact with each other to prevent wear

– Cooling: because the compressor head is a technical detail, it will generate heat when operating, while the compressor oil also has a cooling effect. In high power machines, the stator and rotor windings are immersed in oil for the purpose of cooling the motor

– Sealing: there are gaps between the specifications of the compressor head, the compressor oil will have the effect of filling those gaps.

– Cleaning: during long-term operation of the compressor will generate dirt and other impurities, then the compressor oil has the effect of lubricating and cleaning the details.

Reasons for changing chiller compressor oil

Because compressor oil has the effect of cooling, cleaning, sealing, reducing friction, so after a long time of use, the compressor oil will be dirty and then the compressor oil will lose some of its effect. compressor will be reduced, in case the compressor is damaged due to too dirty compressor oil.

Chiller compressor oil change technique:

Step 1: Proceed to collect gas in the system

Step 2: Use a torch or soldering iron to soften the weld on the compressor head and take the compressor out

Step 3: Use N2 gas to blow into the system to push out all the old oil remaining on the two rigs

Step 4: Pour out the old oil in the compressor

Step 5: Check the parameters of the compressor and pour new oil into the compressor, the amount of new oil must be equal to the amount of oil according to the parameters and only add oil with the compressor suction.

Step 6: Weld the compressor when the oil has been changed into the system and vacuum is applied

Step 7: Load gas and run the test

Step 8: Handover

Please contact us GL Commerce for periodic maintenance and maintenance of the Chiller machine

Contact us: GL Commerce Co., Ltd

Address: Thien Ke Hamlet, Thien Ke Commune, Binh Xuyen District, Vinh Phuc Province

Hotline: 02113.555.688

Gmail: contact@glcomvn.com.vn

Web: Glcommerce.com.vn